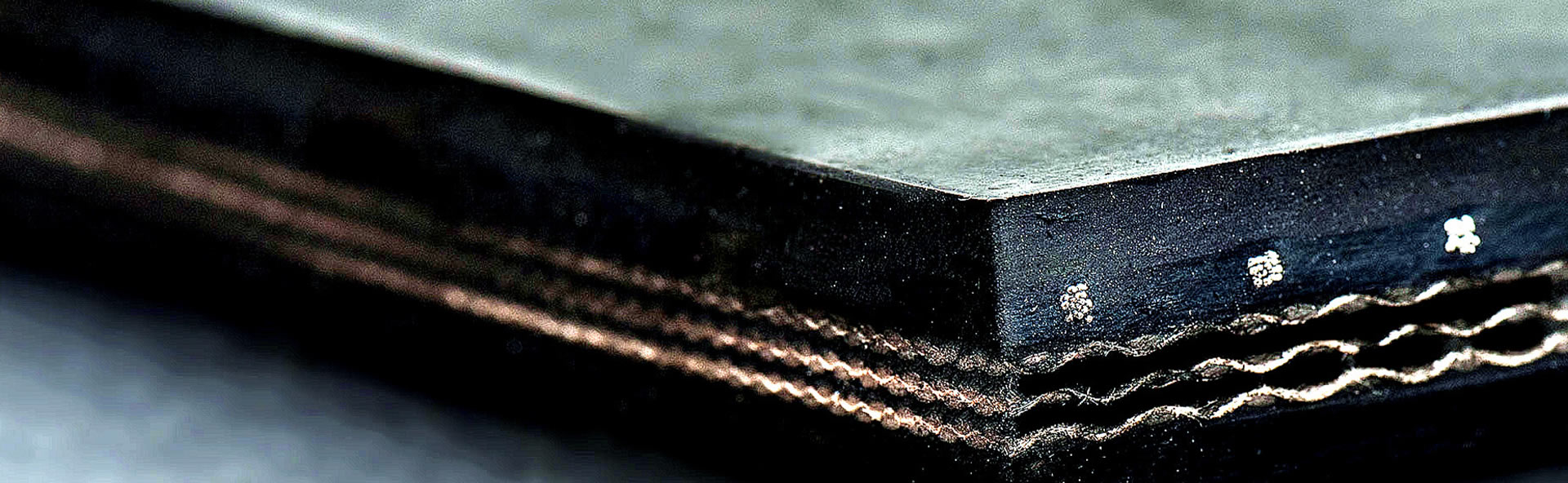

Heat Resistant Conveyor Belts

A normal conveyor belt operates perfectly fine up to 80°C under normal circumstances. Excessive heat can lead to serious damage of the conveyor belt carcass and a shortening of its lifetime. A special rubber compound prevents the distortion of the belt structure and is highly resistant to hot materials such as cement, steel or sand. EPDM or Chlorobutadiene rubber is used to guarantee the required level of heat resistance.

Malollan offers different elastomers of heat resistance:

T1 – MEDIUM

Heat resistance for constant temperature applications of 150 °C (peak 180 °C)

T2 – HIGH

Heat resistance for constant temperature applications of 180 °C (peak 200 °C)

T3 – ULTRA HIGH

Heat resistance for constant temperature applications of 200 °C (peak up to 400 °C)

The rubber compound is acting as a life guard to save the carcass. Additionally, the thickness of the top and the bottom cover rubber also helps to protect the lifetime of the conveyor belt. Therefore the thickness should always be considered – the Malollan service team will support and consult you.

Malollan heat resistant conveyor belts are mainly used in the iron and steel industry, cement plants, the chemical and fertilizer industry as well as in glass and waste plants.